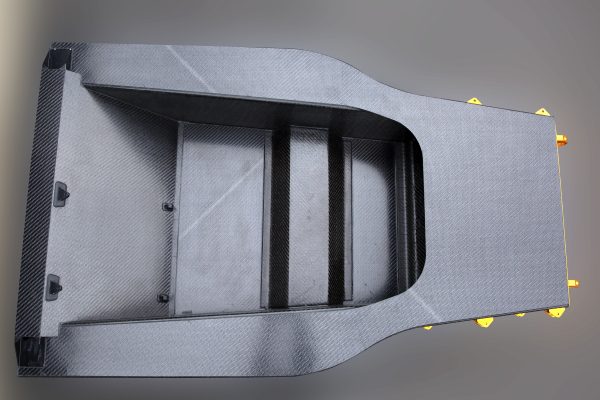

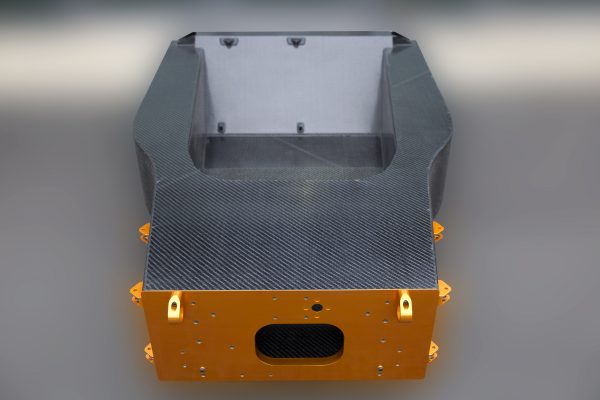

KWM set about developing a carbon composite vehicle platform using thermoplastic materials and innovative manufacturing methods.

The Challenge

- Carbon composite chassis structures are known as being superior to other approaches for reasons of weight, strength, stiffness and thermal management.

- However, conventional CFRP thermosets as traditionally used in motorsport are expensive to process, labour intensive and critically not easily recyclable – a key requirement in the automotive industry.

- The ToPCaT programme aimed to produce a carbon composite vehicle platform for a fraction of the cost of traditional methods.

The Requirements

The key technical requirements of the programme were:

- Performance parity with traditional composite chassis.

- Low tooling costs.

- Modular construction.

- Repeatable manufacturing process.

The Results

In comparison to traditional thermoset manufacture, ToPCaT demonstrated the following benefits:

- Tooling costs: 96% cheaper

- Unit cost: 41% cheaper

- Cycle time: 83% shorter

- Recyclability: Fully (including second life).